- Home Page

- Company Profile

-

Our Products

- SOP Display System

- Adjustable SOP Display Table Holder

- SOP Display Vertical Wall Unit

- SOP Display Information Vertical Desk Unit

- SOP Display Adjustable Information Table Clamp

- SOP Display Desk Holder

- SOP Display Information Panel Plus

- SOP Display Floor Stand Holder

- Plain Display Folder

- SOP Display Information Rotary Desk Unit

- Vertical Wall Unit

- Lighting Poster stand

- SOP Display Information Horizontal Desk Unit

- SOP Display Information Magnetic Panel

- SOP Display Rotary Tower Holder

- SOP Display Information Panel

- Plastic A4 / A3 Sop Document Display Information Folder

- SOP Display Folders

- Horizontal SOP Display Information Holder

- SOP Display Information System

- Plastic Pallet

- Plastic Pallet Size 1100x1100x120 Mm

- Plastic Pallets

- Plastic Pallet 1200X1200X170 mm

- PLASTIC PALLETS 127614

- Plastic Injection Molded Pallet

- HDPE Plastic Pallet

- Plastic Foldable Pallet Box Large Storage Container with Lid

- Plastic Spil Drum Pallet

- Plastic Roto Pallet

- PLASTIC PALLETS 1210160LW

- PLASTIC PALLETS 1210160MW

- Plastic Pallets 1200 X 800 X 160mm

- Industrial Plastic Pallet 1100X1100X120mm

- Plastic Roto Molded Pallets 1200X1000X160mm

- Heavy Duty Plastic Roto Molded Pallets 1200X1200X160mm

- Spill Containment Pallet

- plastic pallet

- plastic pallet manufacturer

- plastic pallet supplier

- Plastic Pallets

- heavy duty plastic pallets

- plastic pallet price

- plastic export pallets

- blue plastic pallets

- Industrial Plastic Pallet

- hdpe pallet

- nilkamal pallets

- Plastic Storage Bin

- File Stationery

- Cardboard Box File

- Blue PVC Box File

- Expandable File Folder

- Double Pocket Button Folder

- Black A4 Paper Box File

- A4 Plastic Folder

- A4 Plastic Laminated Box File

- A4 Plastic Box File

- A4 Laminated Paper Box File

- PVC Ring Binder Files

- Polypropylene Box Files

- Plastic Box File

- PP Ring Binder

- White Box File

- Polypropylene Spring File

- PP Sheet Protector

- Rectangular Paper Board Spring File For Office, Schools, Colleges And Home Documents

- PP Button Folder

- Paper Box Files

- Plastic Ring Binder File

- A-4 Plastic Folder

- PP Display Folder File

- Hard Binding Clip PVC Box File

- spring file

- PP Gapping Folder

- Laminated box file

- PP Report File

- Plastic Ring View File

- Strip File

- Laminated Ring File

- Voucher Box File

- Plastic Box File 1505

- Paper Craft Box File

- PP Cabinet File

- Paper Spring file

- SOP Folder

- Plastic Crate

- Aristo Plastic Crates

- Fabricated Crates

- Fruits Plastic Crate

- Plastic Bottle Crates

- PLASTIC CRATES 32150CC

- Blue Plastic Catering Crate

- Plastic Jumbo Crate

- Plastic Catering Crate

- Catering Crate

- Fabricated Plastic Crate

- Industrial Plastic Crate

- Plastic Industrial Crate

- Plastic Handling Crate

- Plastic Vegetable Crate

- Nilkamal Plastic Crates

- Plastic Crate

- Plastic Stackable Crate

- Plastic Dairy Crate

- Plastic Storage Crate

- Plastic Fabric Crate

- PLASTIC CRATES 43320CC

- PLASTIC CRATES 32065CC

- PLASTIC CRATES 32100CC

- PLASTIC CRATES 32200CC

- PLASTIC CRATES 43275CC

- PLASTIC CRATES 43240CC

- PLASTIC CRATES 43175TP

- PLASTIC CRATES 43220CC

- PLASTIC CRATES 43175SP

- PLASTIC CRATES 43175(HW)CC

- PLASTIC CRATES 43175(LW)CC

- PLASTIC CRATES 43150CC

- PLASTIC CRATES 43120CC

- PLASTIC CRATES 43100CC

- PLASTIC CRATES 43090CC

- PLASTIC CRATES 43080CC

- PLASTIC CRATES 43065CC

- PLASTIC CRATES 53360/CH/CC

- PLASTIC CRATES 53250CH/CC

- PLASTIC CRATES 53150/CH/CC

- PLASTIC CRATES 53200SP

- PLASTIC CRATES 53100 CH/CC

- PLASTIC CRATES 64325/CH/CC

- PLASTIC CRATES 64285CH/CC

- PLASTIC CRATES 64245CH/CC

- PLASTIC CRATES 64225/CH/CC

- PLASTIC CRATES 64180/CH/CC

- PLASTIC CRATES 64160/CH/CC

- Vaccine Carrier

- Pallet Truck

- Courier Bag

- Display System

- Office Essential

- SOP FOLDER

- PACKAGING PRODUCT

- ICE BOXES

- WASTEBINS

- Black Plastic Dustbin

- Stainless Steel Open Perforated Dustbin

- SS Color Coded Dustbin

- Plastic Industrial Waste Bin

- Stainless Steel Swing Dustbin

- Hanging Dustbins

- Colored Dustbin

- Plastic Industrial Waste Bins

- Stainless Steel Colored Dustbins

- Plastic Waste Bin

- 1100 Ltrs Plastic Dustbins

- Stainless Steel Spit Bin

- Stainless Steel Open Plain Dustbins

- Plastic Biomedical Dustbin

- Stainless Steel Ashtray Bin

- Stainless Steel Push Can Dustbin

- Plastic Dustbin

- White Plastic Bin

- Wheeled Plastic Dustbin

- Stainless Steel Pedal Plain Dustbin

- Plastic Biomedical Waste Dustbins

- Plastic Swing Dustbin

- Stainless Steel Pedal Perforated Dustbin

- Stainless Steel Pedal Coloured Dustbin

- Stainless Steel Perforated Pedal Dustbin

- Stainless Steel Pole Hanging Dustbin

- Paddle Dustbin

- Stainless Steel Dustbin

- Stainless Steel Ash Can Bin

- SS Open Perforated Dustbin

- Stainless Steel Bin

- Plastic Dome Waste Bin

- SS Swing Dustbin

- Plastic pedal Dustbin

- Plastic Wheel Dustbin

- Plastic Dome Dustbin

- Bio Mediacal Waste Bin

- DISPLAY BOARDS

- Black Perforated Display Board

- Grey Felt Pin Notice Board

- Golden Groove Perforated Board

- Chalk Magnet Board

- Display Board With Stand

- Factory Display Kanban Post Board

- Key Board Cover Board

- Combination Board

- White Chart Holder Board

- Notice Board

- Groov Display Board

- Pin UP Notice Felt Board

- Pin UP Notice Felt Board With Cover

- White Display Board

- White Display Magnet Board

- SOP Display System

- Contact Us

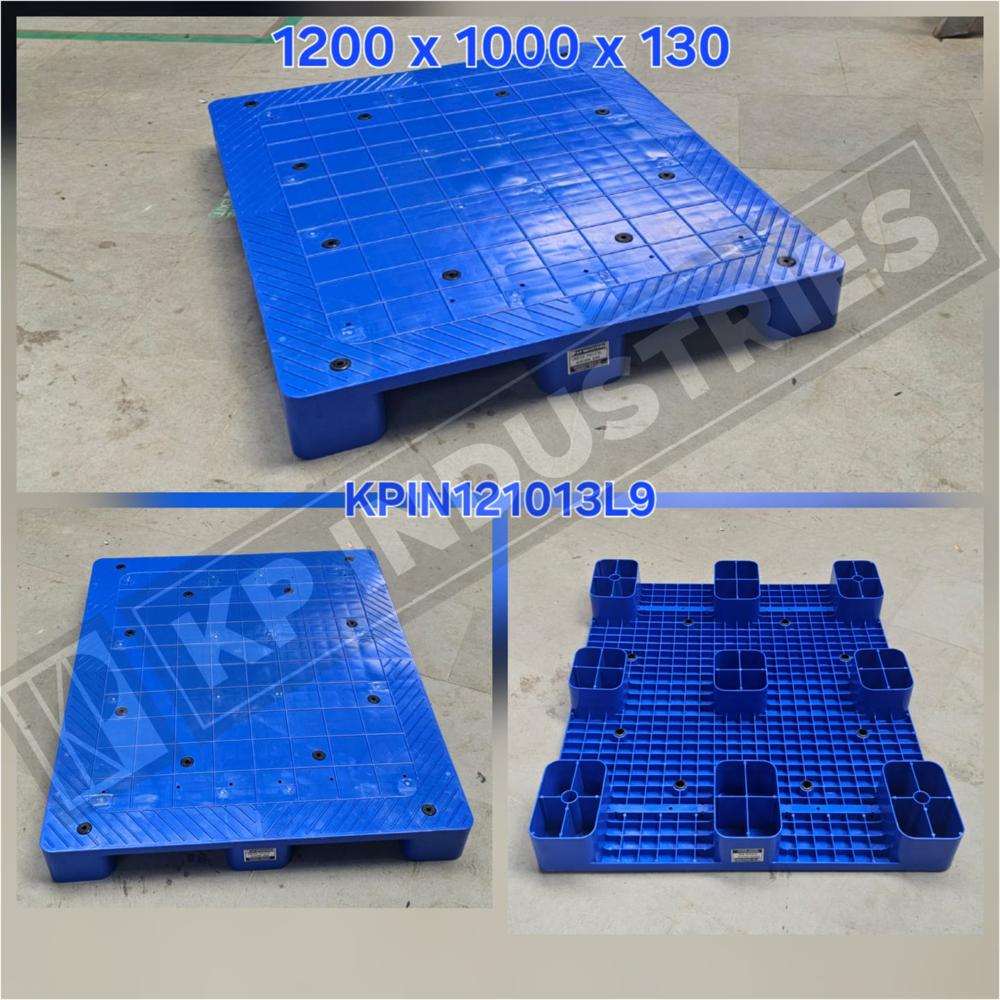

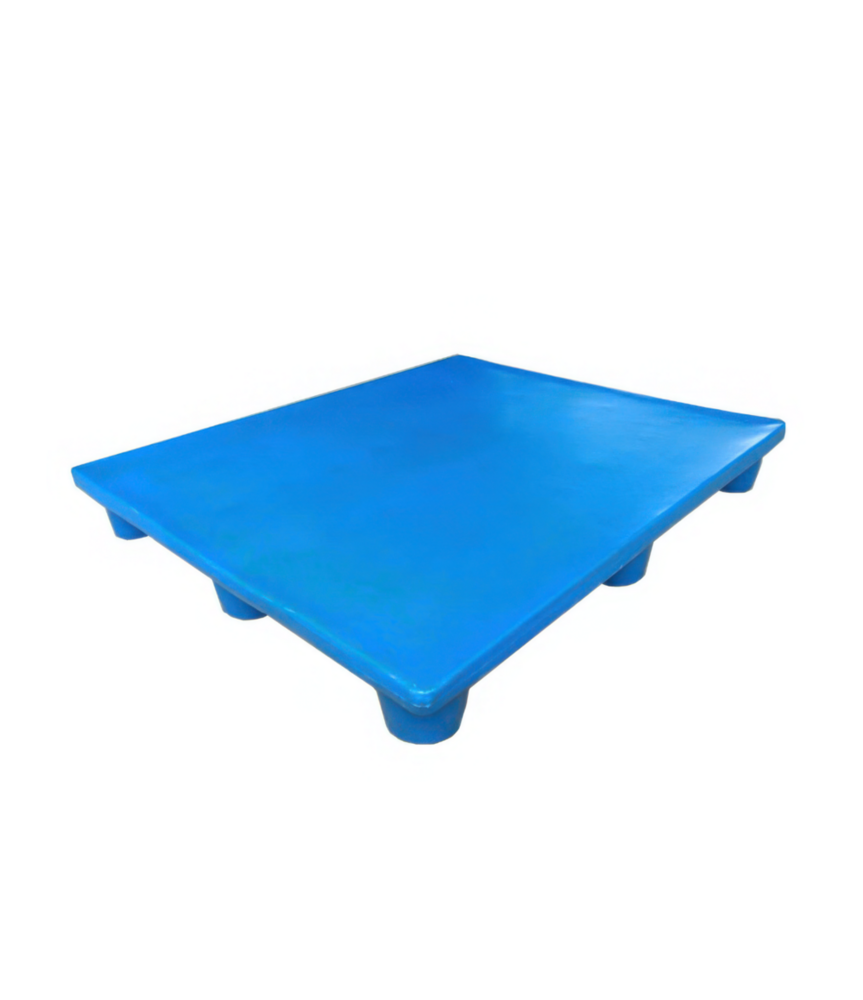

HDPE Plastic Pallet

1299.0 INR/Piece

Product Details:

- Dimension (L*W*H) 1100 x 1100 Millimeter (mm)

- Static load 2000

- Load Capacity 700 - 800 Kilograms (kg)

- Deck Type single

- Dynamic Load 1000

- Material [, ', P, l, a, s, t, i, c, ', ]

- Plastic Type HDPE

- Click to view more

X

HDPE Plastic Pallet Price And Quantity

- 10 Piece

- 1299.0 INR/Piece

HDPE Plastic Pallet Product Specifications

- HDPE

- 1100 x 1100 Millimeter (mm)

- 1100 x 1100

- 700 - 800 Kilograms (kg)

- 2000

- single

- Blue

- 1000

- [, ', P, l, a, s, t, i, c, ', ]

HDPE Plastic Pallet Trade Information

- Gujarat

- c, [, ', C, a, s, h, , A, d, v, a, n, c, e, , (, C, A, ), ', ,, , ', C, a, s, h, , i, n, , A, d, v, a, n, r, s, ', e, , (, C, I, D, ), ', ,, , ', O, t, h, e, ]

- 2000 Piece Per Week

- 1 Week

- No

- Standard

- , [, ', A, l, l, , I, n, d, i, a, ', ,, u, j, a, ', G, r, a, t, ', ]

Product Description

Our HDPE (High Density Poly Ethylene) Plastic Pallet is designed in blue colored plastic. It immensely utilized in industries, residential areas and household to keep the heavy objects in place without damaging the floor. This is used as a reinforcement structure for countless materials such as washing machines, fridges, industrial machinery, packed products and many more items. It is completely resistant against chemicals, water, stains, abrasions and other impacts that easily damage the other availed plastic pallets. Besides, this can be outlined in personalized configurations of the customers to suit their requirements. It is perforated to not induce mold, fungus and other microbial substances when installed for longer period without any handling.

Key Features of HDPE Plastic Pallet:

- Used as a platform for numerous products

- Both industries and households avail it

- Integrated with small elements to support the whole structure

- Secures the flooring from scratches and stains

Product details

|

Country of Origin |

Made in India |

|

Shape |

Rectangular |

|

Material |

Plastic |

|

Color |

Blue |

|

Usage/Application |

Industrial |

FAQs of HDPE Plastic Pallet:

Q: What is the load capacity of HDPE Plastic Pallet?

A: The load capacity of HDPE Plastic Pallet is 700 - 800 Kilograms (kg).

Q: What is the dynamic load capacity of HDPE Plastic Pallet?

A: The dynamic load capacity of HDPE Plastic Pallet is 1000.

Q: What is the static load capacity of HDPE Plastic Pallet?

A: The static load capacity of HDPE Plastic Pallet is 2000.

Q: What is the size of HDPE Plastic Pallet?

A: The size of HDPE Plastic Pallet is 1100 x 1100 Millimeter (mm).

Q: What is the forklift and handlift capacity of HDPE Plastic Pallet?

A: HDPE Plastic Pallet has a 4-way forklift and handlift capacity.

Q: What is the entry type of HDPE Plastic Pallet?

A: The entry type of HDPE Plastic Pallet is 4-way.

Q: What is the deck type and color of HDPE Plastic Pallet?

A: The deck type of HDPE Plastic Pallet is single and the color is blue.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Plastic Pallet' category

Send Inquiry

Send Inquiry Send SMS

Send SMS